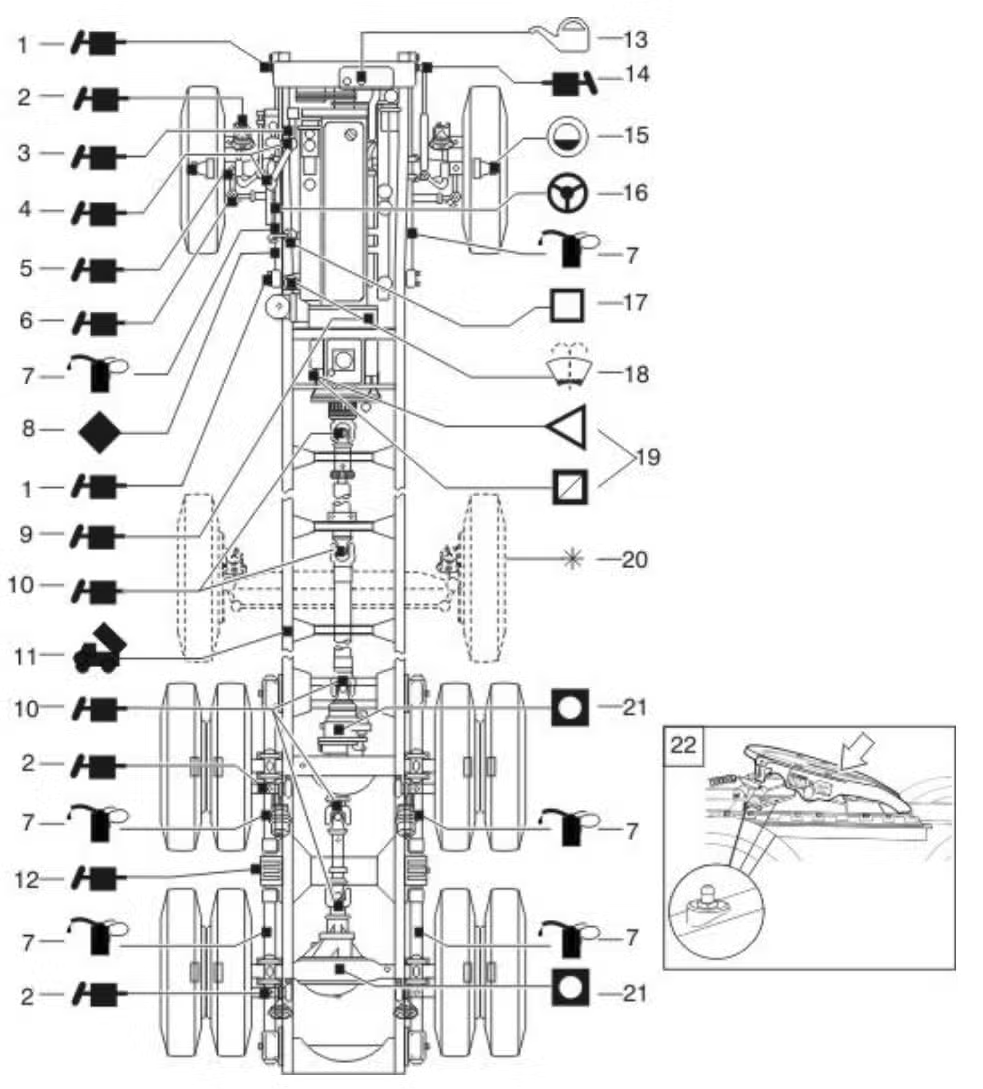

Volvo Truck Grease/Lubrication Chart

April 22, 2018Don't miss a grease fitting on your next grease job. We've published this lubrication chart to show you the grease fittings on your Volvo Truck. Please note, trucks with bodies and specialized equipment may have additional grease and lubrication points.

Make sure that grease fittings are cleaned off before filling grease. Dirt on the fitting that is not cleaned off is pushed into the part with the new grease. Always fill grease to the point where old grease and contaminants are forced out from the part and only new grease comes out. If grease cannot be filled so old grease is forced out or if new grease exits without pushing old grease out, note this on the form for repair. If a fitting does not accept lubrication due to damage or internal stoppage, replace with a new fitting.

Do not heat part for better grease application where rubber or plastic parts are involved.

Remove excess grease from fittings, spring shackles, and other surfaces.

The numbers in the lubrication chart correspond with the numbered notes on the next pages. Read these notes before selecting a lubricant.

|

Grease |

|

Hub Oil |

|

Engine Oil |

|

Hydraulic Oil |

|

Steering Fluid |

|

Coolant |

|

Automatic Transmission Fluid |

|

Manual Transmission Fluid |

|

Rear Axle Oil |

|

Brake Fluid |

|

Windshield Washer Fluid |

|

Lubricate |

|

Dump Body Oil Reservoir Level *For Dump Trucks only |

Lubrication Chart Notes

- 1. Spring hanger: Use a lithium based grease with specification API NLGI Number 2. When lubricating the left and right sides of the front springs, lift the axle off of the floor, suspend the frame with axle stands and lower the axle. The spring bushings are now in the position where grease can be added to the contact surfaces.

Note: The rock guard will have to be removed (if equipped).

Note: Always grease a VOLVO front axle with the wheels on the ground.

Note: To grease non-VOLVO axles, they are typically greased with the wheels on the ground. Consult with the axle manufacturer for the latest recommendation.

- 2. Slack adjuster: Do not grease till 1st scheduled maintenance interval.

Note: See manufacturers specifications for specific grease. Adjust according to the specific slack adjuster manufacturing specifications.

Brake cam Use a lithium based grease with EP additives to specification API NLGI Number 2.Note: If the brake cam seal does not purge, make sure the inner seal does not purge into the brake drum and onto the brake linings.

- 3. Steering gear: Use a lithium based grease with specification API NLGI Number 2. Only use a hand-operated grease gun. The high pressure from an air operated grease gun will damage the seal.

- 4. Drag link and steering shaft: Use a lithium based grease with specification API NLGI Number 2.

- 5. Kingpin, upper and lower: Use a lithium based grease with specification API NLGI Number 2.

Note: Always grease a VOLVO front axle with the wheels on the ground.

Note: To grease non-VOLVO axles, they are typically greased with the wheels on the ground. Consult with the axle manufacturer for the latest recommendation.

- 6. Tie-rod: Use a lithium based grease with specification API NLGI Number 2.

Note: VOLVO axles may use a greased-for-life tie-rod. No provisions for adding grease are available.

7. Leaf Springs: Front and rear leaf spring eye pins, should be pressure lubricated with chassis grease. Vehicles equipped with multi-leaf springs should also have, the leaves lubricated with a spray gun or brush using a rust inhibiting oil.

Keep grease and oil, off of rubber bushings. Failure to do so will result in component damage.

Keep grease and oil, off of rubber bushings. Failure to do so will result in component damage.

-

Note: If the vehicle is operated in sandy or dusty environments, the spring ends should be left dry. Dirt and grease can mix, resulting in a "sandpaper" action that may cause premature wear to the spring ends.

- 8. Brake fluid and clutch reservoir: (if equipped) Check the fluid level in the reservoir. Add brake fluid if necessary. Use only DOT 4 brake fluid in the clutch release system. Mixing DOT 4 brake fluid with petroleum-based oil will cause seal damage which will cause leakage.

- 9. Clutch bearing linkage: Use a lithium based grease with EP additives to specification API NLGI Number 2.

Note: Inspection cover removal is necessary. Lubricate according to Eaton's lubrication document and reinstall the inspection cover. See http://www.roadranger.com for the latest heavy-duty clutch service information.

- 10. U-Joints: Propeller shafts come fully grease and ready for vehicle operation. No grease should be added at assembly plant.

Note: Propeller shaft that have plastic caps over the grease fittings have maintenance free U-joints and caps should not be removed.

- 11. PTO/Hydraulic reservoir.

- 12. Rear suspension (48k-70k suspension): When lubricating the spring pin bushing use a lithium based grease with specification API NLGI Number 2.

Note: Newer versions may have a rubber bushing that does not need lubrication. - 13. Coolant level: Add coolant if necessary. Only use pre-mixed clean water and coolant in a 50/50 mix.

Add only the same type coolant, that is: extended life or standard. - 14. Steering assist cylinder: Use a lithium based grease with EP additives to specification API NLGI Number 2 to grease both ball joints.

- 15. Front oil lubricated wheel bearings (if applicable): Oil-filled hubs change oil at 160,000 km (1000,000 mi) or 12 months or when the hub is removed for repairs or other routine maintenance.

- 16. Power steering fluid: Check the fluid in the reservoir with the dipstick. Add oil if necessary. Use ATF Dexron® III or better. Change fluid every 240,000 km (150,000 miles). Change filter every year.

Use a lithium based grease with specification API NLGI Number 2. - 17. Engine oil and filter: For oil change schedule see service information in Function Group 1, Oil and Filters, VOLVO Components.

- 18. Windshield washer fluid level:

- 19. Automatic and manual transmission:

Automatic transmission: Use Dexron® III or better automatic transmission fluid. See the manufacturer's operator manual for intervals and quantity.

Manual transmission: Use a mineral or synthetic oil. Check oil level periodically. The level should be at the bottom of the inspection hole.

I-Shift transmission: With the vehicle level, the oil should be between the maximum and minimum levels on the sight glass. Only use VOLVO approved oils. Refer to Function Group 1 for the list of the approved oils. - 20. Auxiliary axle(s): If equipped with auxiliary lift axles use a lithium based grease with specification API NLGI Number 2. Also, lubricate the brake, cams, slack adjuster and tie-rod ends.

- 21. Rear axle: Check the oil level in the differential by removing the fill/level plug in the housing. The oil should be level with the bottom of the fill/level plug hole. Add oil if necessary.

Most rear differentials have a large screw and nut protruding from the housing. The screw and nut hold the thrust plate shoe against the ring gear and are not to be confused with the fill/level plug.

Most rear differentials have a large screw and nut protruding from the housing. The screw and nut hold the thrust plate shoe against the ring gear and are not to be confused with the fill/level plug.

-

Note: Refer to service information in Function Group 1, Oil and Filters, VOLVO Components for Oil Types.

- 22. Fifth wheel: The fifth wheel and slider assemblies should always be re-lubricated after steam cleaning or at least every oil change.

Note: A heavy coating of grease is recommended on the fifth wheel plate by using the grease gun or a putty knife by direct application to the top of the plate.

Due to different manufacturers of 5th wheels and models, some 5th wheels may not have grease fittings. Use a lithium based grease with specification API NLGI Number 2 on tracks and moving components.